11.3 The Benefits and the Risks of Participating in a Supply Chain

LEARNING OBJECTIVES

- Understand the major benefits to be derived from adopting a supply chain management system.

- Understand the challenges of creating such a system.

- Understand the technical and managerial risks associated with supply chain management.

- Recognize the benefits for a small business in adopting supply chain management.

The Benefits of Successful Supply Chain Management

For any small business, a commitment to developing a supply chain management system is not a small undertaking. It involves the commitment of significant financial resources for the acquisition of appropriate software. Policies and procedures must be changed in accordance with the needs of the new system. Personnel must be trained in not only using the new software but also adapting to new ways of doing business. Small businesses accept these challenges of adopting supply chain management systems because such systems are viewed as being important for long-term survival and because businesses anticipate substantial management and economic benefits.

The management benefits of supply chain management system include the following:

- Silo busting. By their very nature, supply chain management systems improve communication across all functions within a business. This leads to employees having a better understanding of the entire operations of a business and how their work relates to the overall benefits of the business.

- Improve communications with suppliers and customers. Improved communications with customers enhances the overall value provided to those customers. The improvement in customer satisfaction leads to longtime relationships, which yields significant economic benefits. Improved communications with suppliers improve the overall operational efficiency of both participants, reduce costs, and improve profits.

- Supplier selection. Supply chain management systems can help businesses evaluate prospective suppliers and monitor the performance of current suppliers. This capability can lead to strategic sourcing and significant cost savings plus improvement of the when- and where-needed variables.

- Improvements in purchasing. The automation of purchasing reduces errors and improves the economic efficiency of the purchasing function. Disciplined purchasing can allow for the full exploitation of available discounts.

- Reduction of inventory costs. Supply chain management systems can produce significant cost savings across all levels of inventory. Improved forecasting and scheduling will lead to increases in inventory turns and a corresponding reduction of costs.

- Improvements in operations. Improved quality control reduces the scrap rate, which in turn can have significant cost savings. Better production scheduling translates into producing what is needed when it is needed. The business does not have to spend additional money trying to expedite the production of particular orders to customers. The cost of goods sold is reduced in this manner. An additional benefit of supply chain management systems is that they lead to better utilization of plant and equipment. Great utilization translates into less likelihood that unneeded assets will be acquired, which has major financial benefits.

- Error reduction. By automating processes, billing errors and errors associated with purchasing and shipping quantities can be reduced. This not only saves money but also improves satisfaction with both suppliers and customers.

- Improvements in transportation operations. Accurate deliveries reduce returns and their associated costs. Sophisticated shipping models can reduce the overall cost of transportation.

- Additional financial benefits. Such systems can improve the collections process, which impacts customer relations, reduces bad debts, and improves cash flow.

The Risks Associated with Supply Chain Management

The major risks associated with a supply chain management system fall into two categories: technical and managerial.

Michael Porter’s five forces model is a model of the major factors that contribute to an industry’s overall structure. It also points to factors that might affect the overall profitability of the particular business within that industry. The greater the strength of these forces, the greater the challenge to make above average return profits for businesses in that industry. It is useful to review two of those forces—the power of suppliers and the power of buyers—and reexamine how they might influence the profitability of any business in the supply chain.

Porter identifies the following factors that might contribute to the overall strength of each force. He argued that suppliers are powerful (see Figure 11.3 “The Core Elements of a Supply Chain Management System”) when the following occurs:

- They are concentrated. When an industry is dominated by only a few suppliers, these suppliers generally have a greater ability to dictate terms to their customers. The mining company DeBeers, which controls more than 50 percent of the world diamond production, is able to set the selling price of diamonds for most of the world’s jewelers.Mason A. Carpenter and William G. Sanders, Strategic Management and Dynamic Perspective (Upper Saddle River, NJ: Prentice Hall, 2008), 108. It should be pointed out, however, that in some cases concentration, particularly a duopoly, provides an opportunity for customers to force the two competing firms to compete more readily against each other. Think of the situation of Boeing and Airbus and their relationship to their customers—various airlines. At present, there are only two major producers of commercial aircraft, and airlines sometimes obtain better deals from one manufacturer because of their desire to maintain parity in market share.

- The size of the suppliers is large relative to the buyers. Suppliers are powerful when they are large and sell to a set of fragmented buyers. Think of the largest oil companies that sell gasoline to independent stations. The power in this scenario lies with the large oil companies.

- Switching costs are high. Suppliers have power when the cost of switching to an alternative supplier is expensive. Many businesses stay with Microsoft products because to do otherwise means that they would have to repurchase new hardware and software for the entire organization.

Problems may also arise from a heavier reliance on one customer in the supply chain. Even large companies need to be aware of their relative strength in the supply chain. Rubbermaid is the most admired corporation in America, as voted by Fortune magazine in 1993 and 1994, yet it had significant difficulties when dealing with one of its major customers—Walmart. In the early 1990s, Rubbermaid found that the cost for a key ingredient—resin—had increased by 80 percent.Mary Ethridge, “News about the Wal-Mart Struggle,” accessed February 2, 2012, www.dsausa.org/lowwage/walmart/Dec17_03.html. Walmart’s almost total focus on lowering its prices led it to drop many of Rubbermaid’s products. This began a downward spiral for Rubbermaid, which led to its acquisition by Newell Inc. Rubbermaid went from the status of the most admired corporation to being a basket case because it failed to recognize its excessive dependence on one customer.

Web Resources

The Benefits of Supply Chain Management

A list of benefits from SAP, a software company.

searchsap.techtarget.com/feature/Checklist-Quantifying-Supply-Chain-Management-benefits

The Risks of Supply Chain Management

A Forbes article on the risks associated with supply chain management.

www.forbes.com/2006/11/15/risks-supply-chain-strategies-biz-logistics-cx_rm_1115strategies.html

Risk and Rewards in Supply Chain Management

A Harvard working paper.

KEY TAKEAWAYS

- There are significant benefits for businesses that adopt supply chain management systems.

- The benefits stem from improved customer relations, cost cutting, and increased operational efficiencies.

- The adoption of a supply chain management perspective can pose risks.

- Businesses must consider the relative power of both their suppliers and their customers.

EXERCISES

- Interview the owners of local businesses who say they have some form of a supply chain management system and ask them if they believe they have benefited from the system.

- Ask them how they have benefited.

- Ask them to identify the major problems they had with implementing and using the system.

- Ask them if they believe they have the “power” in their supply chain or if the “power” is in the hands of their suppliers.

11.4 The Three Threads

LEARNING OBJECTIVES

- Understand how customer value is enhanced by supply chain management.

- Understand how cash flow can be increased, in the long term, by using supply chain management.

- Understand the various computer programs that make up a supply chain management program.

- Recognize the risks that can stem from adopting a single supplier program.

Customer Value Implications

Throughout this text, we have emphasized the importance for small businesses to constantly focus on the notion of improving value for their customers. Successfully implementing a supply chain management system offers tremendous possibilities for not only improving value to customers but also significantly enhancing the capabilities and profitability of the small business itself. Supply chain management improves customer value in the following ways:

- Reduced inventory. A well-executed supply chain management system means that customers receive orders when they need them. Further, this does not necessarily imply that the supplier will be holding the inventory for the customer—although that might occur. It refers to the fact that better communication and better scheduling may enable the supplier to produce the item exactly when it is needed.

- Improvement in the order accuracy. Supply chain management should guarantee that when orders are shipped, the right items are shipped in the right quantity. This does not disrupt the production of the customer and eliminates product returns, which results in economic benefits for both the customer and the supplier.

- Reduced cycle time for product development. To ensure success, the customer and the supplier must develop new levels of trust. This trust will evolve into a long-term relationship. Both parties begin to know each other better, including each other’s needs and capabilities. As this evolves, the supplier is in a better position to help the customer develop new products far more rapidly. It greatly reduces the product cycle time.

- Financial benefits. These value improvements all translate into significant cost savings. Cost savings experienced by the supplier can be transferred into cost savings for the customer. Relatively modest improvements in inventory reduction, reduced safety stock size, reduce stockouts, improved order fill rates, and reduced transit time can yield surprisingly large financial benefits to both parties.

- Peace of mind. Having a supplier that one can trust to accurately deliver items in a timely low-cost fashion, which has also developed contingency plans to cope with potential problems, is relatively unique and provides the customer with a high level of comfort. One may be unable to place an economic price on such peace of mind.

Cash-Flow Implications

It must be recognized that committing to a supply chain management system from scratch will entail a major investment. New approaches to software can reduce both the cost and the risk of such a commitment. However, businesses will want to recoup most of the investment as quickly as possible—perhaps six months or less. Given the potential for cost savings, the impact on increasing cash flow should be obvious.

What is not obvious is the potential for significant improvements in cash flow from minor improvements generated by supply chain management systems. To illustrate this, let us look at an example adapted from Coyle et al. (2009).John J. Coyle, C. John Langley, Brian Gibson, Robert A. Novak, and Edward J. Bardi, Supply Chain Management: A Logistics Perspective, 8th ed. (Mason, OH: South-Western, 2008), 301. Assume that a firm is in the following situation: It ships orders to customers; if the orders are incomplete or inaccurate, the firm assumes the full cost of the return and follow-up shipping. When an incorrect shipment is made, to ameliorate their upset customers, the firm takes $100 off the bill. However, when some customers find that the order is incomplete or inaccurate, they are so upset that they cancel the order. Here are the data:

| Number of orders per year | 50,000 |

| Number of items per order | 25 |

| Profit per unit ($) | 30 |

| Price reduction for incorrect order ($) | 100 |

| Back order cost per order ($) | 200 |

| Percentage of totally correct orders | 90 |

| Percentage of incorrect orders cancelled | 25 |

It can be readily seen that the profit per order is $750 (25 × $30). We now examine the lost cash flow from the situation. The lost cash flow has several components. The first component is the back order cost, which is composed of the number of orders that will have to be back filled. The second component is associated with the losses from the incorrect orders that were canceled. The last component is the price reduction for the incorrect order.

lost cash flow = backorder costs + cancelled sales costs + price reduction costs

These can be computed as follows:

lost cash flow = [number of orders × (1 − percentage of totally correct orders) × backordered cost per order][number of orders × (1 − percentage of totally correct orders) × percentage of incorrect orders cancelled × profit per order] + [number of orders × (1 − percentage of totally correct orders) × price reduction for incorrect order]

Now let us substitute the correct values into this equation.

lost cash flow = [50,000 × (1 − .90) × $200] + [50,000 × (1 − .90) × (.25) × $750] + [50,000 × (1 − .90) × $100]lost cash flow = $1,000,000 + $937,500 + $500,000 = $2,437,500

We now assume that an “improved” supply chain management system has been installed. The percentage of correctly filled orders increases from 90 percent to 96 percent. If we substitute 96 percent into these equations, we find that the new lost cash flow would decrease to $975,000. This means that a 6 percent increase in order accuracy leads to a 60 percent decrease in the loss of cash flow.

Implications of Technology and the E-Environment

It should be obvious that contemporary supply chain management cannot be conducted through paper and pencil procedures. The backbone of today’s supply chain management is software. Initially, it would be impossible to think of developing such systems without electronic data interchange. Today, the Internet serves as the basis for sharing communication between suppliers and customers. However, there is more to the technology behind supply chain management system than merely the exchange of data.

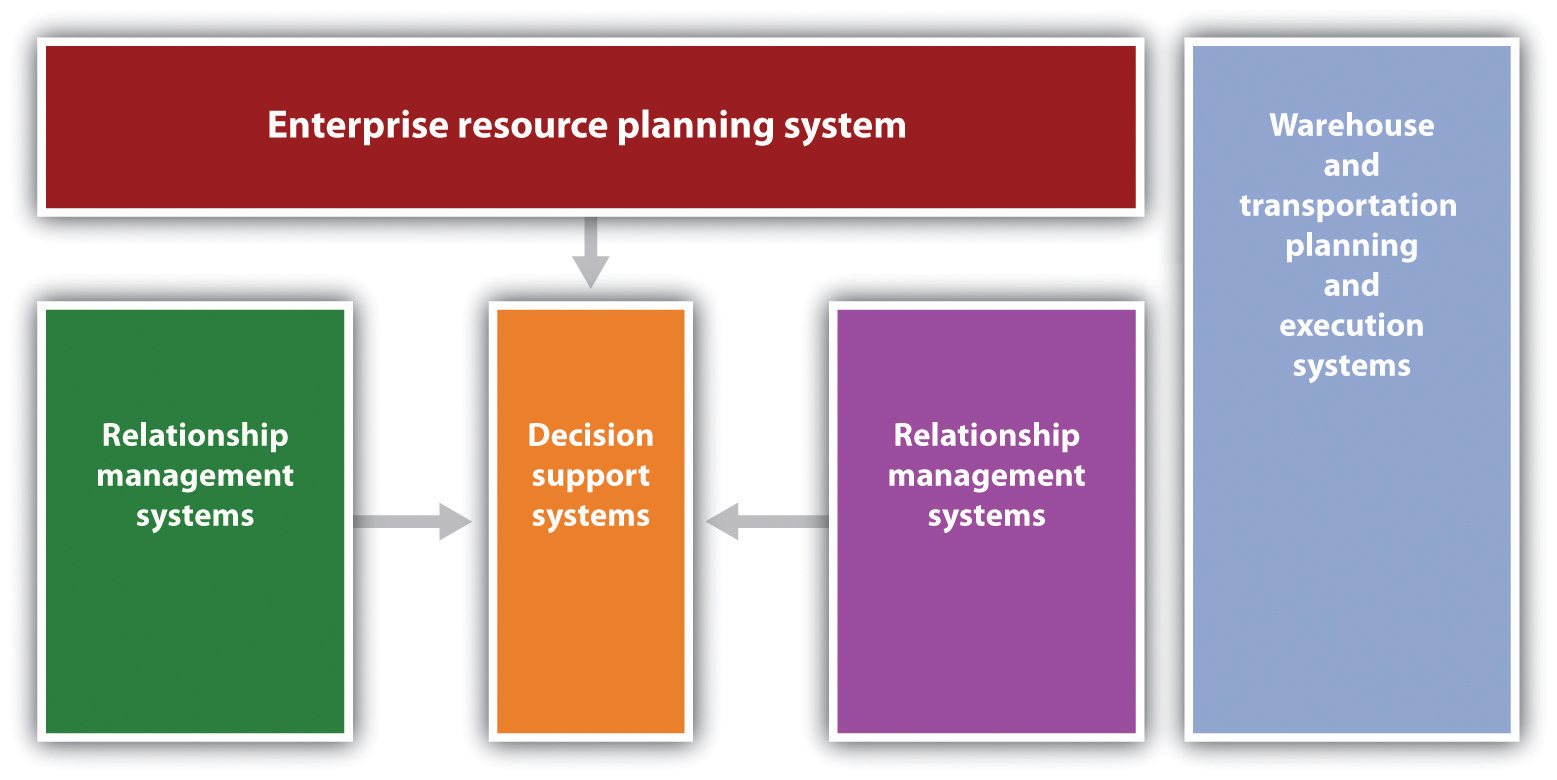

Supply chain management requires several types of software packages and the need to successfully integrate them. One can identify several major software components of a supply chain management system (see Figure 11.4 “Schematic for a Supply Chain Management Information System”). One section would be supplier relationship management programs. These programs involve planning and controlling the actions with upstream suppliers. Such programs would cover many aspects of procurement—supplier analysis, order execution, payment, and performance monitoring.Joel D. Wisner, G. Keong Leong, and Keah-Choon Tan, Principles of Supply Chain Management: A Balanced Approach (Mason, OH: South-Western, 2004), 76. There would also be customer relationship management (CRM) software that would handle all interactions with customers. Enterprise resource planning (ERP) would handle the necessary integration of all data. ERP coordinates data flows from finance, accounting, and operations to provide management with a seamless overview of the performance of a business. It may also have a decision support system, which allows for data manipulation or the use of analytical modeling tools to provide a better decision-making environment. It may involve using mathematical programming models to optimize decisions. Another set of modules dedicated to logistics would focus on the optimal use of warehousing and shipping. These functions are sometimes handled externally by either a third- or fourth-party logistics provider.

Figure 11.4 Schematic for a Supply Chain Management Information System

Not too long ago, the acquisition and the operation of these software packages would have been prohibitive for most small businesses from both a cost standpoint and a technical standpoint. Fortunately, software providers now recognize that small and midsize businesses represent a tremendous market for supply chain management software. It was estimated in 2008 that the demand for business enterprise software applications for small and midsized businesses would grow at a nearly 11 percent annualized growth rate until 2012.“Small and Medium-Sized Business Enterprise Applications Market to Grow to $80.3 Billion by 2012,” Business Wire, June 11, 2008, accessed February 2, 2012, www.reuters.com/article/2008/06/11/idUS117514+11-Jun-2008+BW20080611. Microsoft, Oracle, and SAP have developed systems that enable small to midsize companies to handle all the complexities of global supply chain management.Carol Lawrence, “Enterprise Resource Planning Software Become More Accessible to Small and Midsize Companies,” McClatchy Tribune Business News, August 8, 2010. Large software vendors such as Oracle estimated that the midmarket clientele was approximately 4,500 out of their total client base of 7,000 customers. Several factors can be attributed to this rapid growth in small to midsize businesses. The first was that many software providers were willing to offer in-house installation at a predictable cost. Second and perhaps the most important factor is the increasing move to cloud-based software, where software resides on an external server to which the businesses are connected to via the Internet. It provides several substantial benefits to small businesses: lowers software and hardware costs, installation is significantly easier, maintenance and training costs are lower, and free upgrades may sometimes be available. The use of Internet-based systems also makes it easier to maintain lines of communications with one’s suppliers and customers. Robert LaGarde, president of LaGarde E-business Solution, has stated that “using Internet technology to provide customers with online demand access to supply chain systems is critical to nurturing and growing relationships with customers.”David Hayes, “When Size Doesn’t Matter (in business),” McClatchy Tribune Business News, March 4, 2010. What initially appeared to be a remarkably complex system of programs has now been made available to even very small businesses.

Video Clip 11.16

Impact of RFID Technology on Supply Chain Management

The impact of RFID technology on supply chains.

Video Clip 11.17

Supply Chains and Information Technology

Modern-day supply chains are tasked with responding at lightning speed.

Video Clip 11.18

Future Supply Chain 2016

The main supply chain challenges for consumer products and retail for the next decade.

Video Link 11.1

Japan: The Business Aftershocks

Japan is a small country with a supersized role in the global supply chain (a short ad precedes the video clip).

Web Resources

List of Supply Chain Management Software

A comprehensive list of SCM software with links.

www.capterra.com/supply-chain-management-software

About.com SCM Software

Supply chain management software with links to other sites.

The Benefits of Supply Chain Management Software

Identifies benefits and includes option to download a report on the top fifteen ERP providers.

www.business-software.com/erp/supply-chain/benefits-of-supply-chain-erp.php

KEY TAKEAWAYS

- Supply chain management can enhance customer value in many ways.

- Cost savings brought about by supply chain management systems can produce amplified improvements in cash flow.

- Supply chain management systems can be seen as a collection of interconnected software packages.

- The advent of cloud computing can make supply chain management systems available for small businesses.

EXERCISES

- Interview the owners of five local businesses and ask them how supply chain management has or could enhance their customers’ value.

- For those small business owners who have a functioning supply chain management system, ask them if they have noticed improvements in cash flow attributable to the system.

- Ask them what system(s) they use and why they went with these computer packages.

- Ask them if they have contingency plans for the loss of key suppliers.